|

Design No. X851

Ratings — 1, 1-1/2, 2, 3, 3-1/2, and 4 Hr.

Design No. N851

Restrained Beam Ratings — 1, 1-1/2, 2, 2-1/2, 3, 3-1/2 or 4 Hr.

Unrestrained Beam Ratings — 1, 1-1/2, 2, 2-1/2, 3, 3-1/2 or 4 Hr.

| Size |

W/D |

Required Thickness mm (inches) |

| Rating(minutes) |

| 60 |

90 |

120 |

150 |

180 |

210 |

240 |

| W6 x 9 |

0.34 |

21 |

27 |

32 |

38 |

44 |

50 |

55 |

| W6 x 12 |

0.44 |

21 |

27 |

32 |

38 |

44 |

50 |

55 |

| W8 x 18 |

0.499 |

21 |

27 |

32 |

38 |

44 |

50 |

55 |

| W6 x 16 |

0.58 |

21 |

27 |

32 |

38 |

44 |

50 |

55 |

| W8 x 28 |

0.68 |

20 |

27 |

32 |

38 |

44 |

50 |

55 |

| W10 x 49 |

0.84 |

16 |

27 |

32 |

38 |

44 |

50 |

55 |

| W21 x 73 |

0.98 |

14 |

25 |

32 |

38 |

44 |

50 |

55 |

| W10 x 60 |

1.01 |

14 |

25 |

32 |

38 |

44 |

50 |

55 |

| W12 x 106 |

1.47 |

9 |

17 |

25 |

32 |

40 |

40 |

55 |

| W14 x 132 |

1.56 |

9 |

16 |

23 |

31 |

39 |

39 |

54 |

| W14 x 176 |

1.96 |

7 |

13 |

19 |

24 |

30 |

30 |

46 |

| W14 x 211 |

2.32 |

6 |

11 |

16 |

21 |

26 |

26 |

40 |

| W14 x 257 |

2.78 |

5 |

9 |

13 |

17 |

21 |

21 |

29 |

| W14 x 283 |

3.03 |

5 |

9 |

12 |

16 |

20 |

20 |

27 |

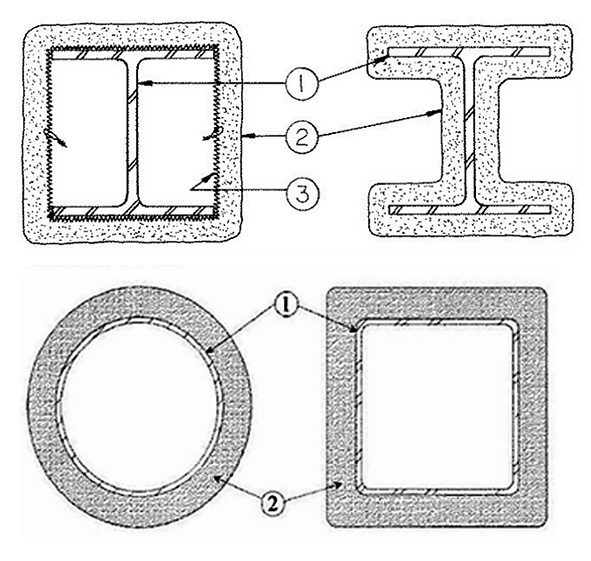

As an alternate to the above table, the required thickness of spray— applied fire resistive material (in inches)

to be applied to all surfaces of wide flange steel columns, in the W/D range of 0.34 to 3.03 and for 1, 1-1/2,

2, 2-1/2, 3, 3-1/2 and 4 hour rating periods, may be determined from the following equation:

Where t = minimum thickness spray— applied fire resistiveve material (rounded up to the nearest 1/16 in. ), T =

Fire resistance period in minutes, for 60, 90, 120, 150, 180, 210 and 240 minutes, W = Weight of steei

column ¡n pounds per Llinear foot, D = Heated perimeter of steel column section in inches.

Thicknesses genenated from the equation shall fall between 3/16 in. and 2-3/16 in. If a calculated thickness

falls outside of this range, a rating cannot be determined.

|

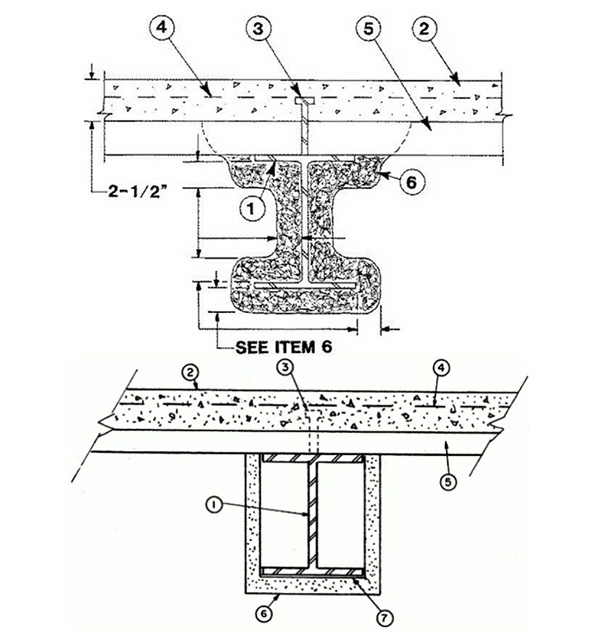

- Inspect the surface before spraying, and remove dust, oil, paint, rust, etc. if any.

- Keep at least 60cm between the construction surface and the nozzle. Keep a right angle from the construction surface. Apply 10~30mm each time, and wait for at least 6 hours before the next application.

- Be sure that the temperature is at least 4 degrees. The mixing ratio of HICOTE SP and water is 1:1.3. Mix them for 2 to 5 minutes before initiating the work.

- Be sure that the area is well ventilated. The surface strengthening and curing process takes about 10 to 15 days. (Basis: 20 degrees)

※ For other details, refer to specifications of Sunghyun Chemical Co., Ltd.

|